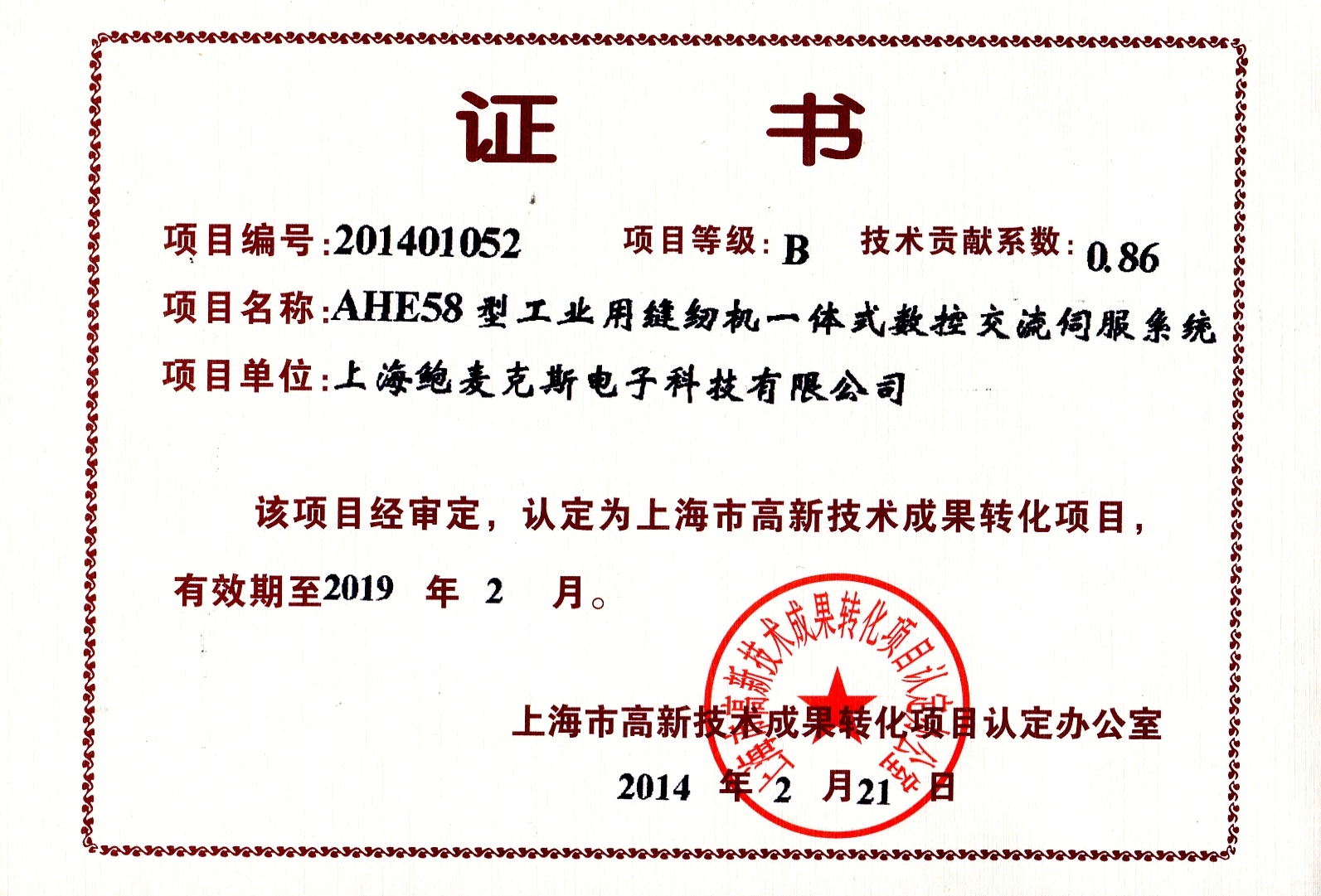

In accordance with requirements of the Several Provisions on Promoting New High-tech Achievement Transformation in Shanghai ([2004] No.52 of HFF) and Shanghai New High-tech Achievement Transformation Project Identification Procedure ([2009] No. 586 of HK), AHE58 industrial sewing machine integrative digital control AC servo system researched and developed by Shanghai Powermax Technology, Inc. was approved as one of Shanghai New Hi-tech Achievement Transformation Projects after the online declaration, preliminary review made by Science and Technology Commissions at district, country level and other competent departments, online expert review and determination made by the new high-tech achievement transformation project identification judging committee, with project grade B, technical contribution factor of 0.86. According to relevant regulations, new high-tech achievement transformation projects identified may enjoy Shanghai new high-tech achievement transformation special funds, interest payments on loans and other preferential policies to support the introduction of talents within the period of validity of identification in accordance with requirements.

Project product-AHE58 industrial sewing machine integrative digital control AC servo system concentrating on allowing supporting industrial sewing machines for the application object is a breakthrough technology tackling on the basis of A5-type system platform developed by the Company, allowing the project to achieve product integrative servo system integration design, to achieve the shift from the electronically controlled "desktop" to the electronically controlled "notebook" and to achieve miniaturized, systematic and integrated development of the servo system on the basis of ensuring the reliable and advanced technical performance through three key technology studies such as the new CNC AC servo system architecture studies, hierarchical finite state machine-based control software system studies, PCB control hardware system studies, etc.

The project product has achieved trimming, thread proding, seam inverting, foot lifting and other basic functions, and has additionally achieved thread clamp function, strengthened the capacity to sew too thick materials and optimized stitch stop effect. And, 16 kinds of functions such as foot lifting soft release, decorative back tacking, stitch cooling and so on can be achieved by parameter setting. Its efficient sewing characteristics, sewing quality, reliability and consistency have reached the international advanced level, and its stability and function expansion have been upgraded with upgrading of domestic and foreign similar products. Currently, the Company achieves its own 10 patents, including 9 new utility patents and one appearance design patient. Currently, the project has entered the stage of industrialization, which can bring very substantial economic and social benefits to sewing equipment manufacturing enterprises and numerous sewing product processing enterprises.